- No products in the cart.

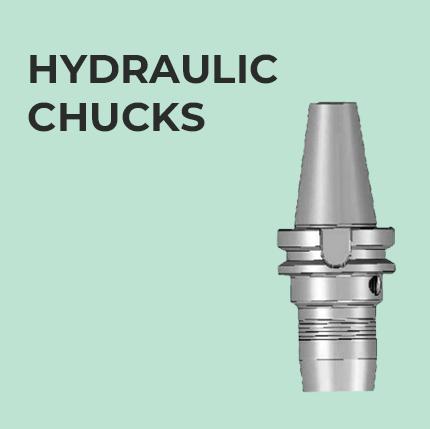

Hydraulic Holders use hydraulic pressure to hold tools, they offer more stable and accurate clamping than any other collets. They are suitable for high-precision machining, especially operations like cutting, drilling, and end milling.

Features :

- Balanced 25000 RPM at G2.5

- Accuracy: 3 Micron or 0.0001" TIR or better

- AT3 Class Taper Accuracy

- Through-tool coolant feature is standard

- High precision pilot holes

- Hardness: HRC 56-58

- Carbon depth 0.8mm +- 0.2mm

- Surface Roughness Ra<0.0005mm

- Crafted from case hardened alloy steel

- Suitable for Drilling, Reaming & Milling operations

At Accu-fix Precision Tools, we offer the best hydraulic holders that are perfect for drilling, milling, and cutting operations in CNC machining. It reduces tool wear and extends tool life, which makes it cost-effective.

Frequently Asked Questions

1. What are the hydraulic holders?

Hydraulic chucks are used on CNC milling machines and are best for the machining operations that require high-precision accuracy and rigidity. They use pressurized hydraulic oil to grip the workpiece in place during operations.

2. What are the differences between hydraulic holders and tapping holders?

The key differences between hydraulic holders and tapping holders are their purpose, features, and applications. Purpose of hydraulic chucks is clamping tools in place while tapping holders are used for cutting threads and drilling holes. Features of hydraulic holders are flexible clamping range and vibration dampening, whereas tapping holders have compact design and are modular. Applications of hydraulic holders are milling, drilling, reaming, while tapping holders are used for cutting threads.

3. What are the taper sizes of hydraulic holders available at Accu-fix precision tools?

At Accu-fix precision tools, we have BT30, BT40, BT50, HSK-A taper sizes available. If you want further information or want to buy you can contact us on

+91 9099600730,

+91 7567975718 or you can also email us at

store@accufixtools.com or

sales@accufixtools.com and in mean time our team reach out to you.

4. What are the features of hydraulic holders from Accu-fix precision tools?

There are various features that make our hydraulic chucks the best choice for your machining operations.

- Our hydraulic holders are made from case hardened alloy steel.

- Provides accuracy of 3 Micron or 0.0001” TIR or better

- AT3 class taper accuracy

- Through-tool coolant feature is standard

- High precision pilot holes

- Hardness: HRC 56-58

- Carbon depth 0.8mm ± 2.0mm

- Surface roughness Ra<0.0005mm

- Balanced 25000 RPM at G2.5

- Best suitable for drilling, milling, reaming operations.

5. What industries use hydraulic holders?

Hydraulic chucks are used in many industries such as aerospace, construction, energy building, milling, drilling, woodworking, metalworking, and construction. Hydraulic holders are used in all these industries to hold specific workpieces in place so while operating they do not slip and provide smooth performance.

Quick Link

- ER Collet

- ER Sealed Collets

- ER Steel Sealed Collets

- ER External Coolant Collets ECD | Jet-Spray

- ER Tap Collets

- ER Tap Sealed Collets

- ER Tap Sealed Jet Spray Collets

- Quick Change Tapping Adapters

- DA Collets Regular

- DA Sealed Collets

- TG Collets

- TG Sealed Collets

- TG Tap Collets

- OZ Collets

- SK Collets | Super Collets

- Straight Collets For Milling Chucks

- Reducation Sleeves For Hydraulic Chucks

- R8 Collets

- Collet Sets

- 5C Collets

- 16C Collets

- 3J Collets

- ER Collet Holders

- Side Lock Endmill Holders

- Shrink Fit Holder

- Facemill Holders

- Morse Taper Holder

- Power Milling Holders

- Hydraulic Holders

- Quick Change Tapping Holders

- ER Straight Shank

- BT Knobs

- CNC Turret Sleeves

- Revolving Live Centers

- ER Collet Nut

- SK Collet Nuts

- ER Spanners

- Tool Locking Device

- Soft Jaws

- Hard Jaws