- No products in the cart.

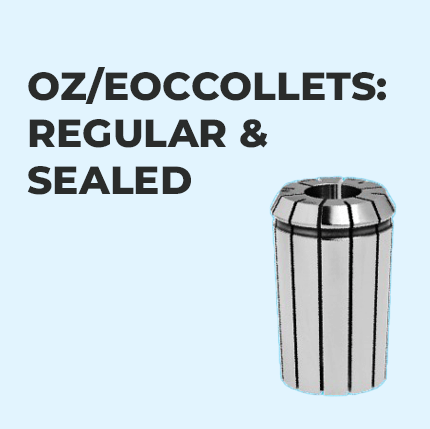

Buy OZ Collets from Accu-fix Precision Tools, used to hold workpieces in centers and routers while CNC machining operations. OZ collets can stretch as per tool size to provide better pressure to tightly hold the tool in the spindle. OZ collets are more rigid and suitable for milling operations.

Features :

- OZ collet series from OZ6 to OZ32

- Fractional Collets manufactured specifically for USA market requirements

- All edges are not only deburred, but additionally rounded for repeatability

- Crafted from high quality European sping steel

- Inch & Metric sizes avaliable

- More clamping force

At Accu-fix precision tools, oz collets are made from high-quality european spring steel to ensure tight grip on tools for better performance ensuring chip evacuation, and long tool life for your machining needs.

Accuracy :

Dimensions :

Frequently Asked Questions

1. What are the OZ collets?

OZ collets are used to hold tools while CNC machining operations in centers and routers. OZ collets can stretch as per tool size to provide better pressure to tightly hold the tool in the spindle.

2. What are the series available of OZ collet at Accu-fix precision tools?

At Accu-fix precision tools, we have the following OZ collet series available: OZ6, OZ8, OZ10, OZ12, OZ16, OZ20, OZ25, OZ32, OZ40. For more information, contact us on +91 9099600730, +91 7567975718 or Email us at store@accufixtools.com or sales@accufixtools.com.

3. How can I buy OZ collets from Accu-fix precision tools?

You can buy OZ collets from Accu-fix precision tools by browsing our OZ collets and selecting the perfect size that suits your machine operations. After that, you can contact us on +91 9099600730, +91 7567975718 or Email us at store@accufixtools.com or sales@accufixtools.com for a quotation. For further details, visit our company.

4. How can I maintain OZ collets from Accu-fix precision tools?

To maintain OZ collets from Accu-fix precision tools, you should consider storing them in a neat and clean place to avoid dust coating on tools. Do lubrication (oil and grease) from time to time for smooth performance, clean the tool before and after use to remove dust and debris to avoid improper alignment, and check for any wear or damage. If you see any sign, replace them with new ones.

5. How does OZ collet differ from ER collets?

OZ collets differ from ER collets by their slot positions. ER collets have slots from top to bottom, while OZ collets have slots only at the top. ER collets compress perfectly around the tool’s length, while OZ compresses unevenly around the tool’s length. ER collets provide even clamping on the tool, while OZ provides tangential clamping on the tool. ER collets are widely used in CNC machining operations, whereas OZ collets are used in CNC routers and machining centers.

Quick Link

- ER Collet

- ER Sealed Collets

- ER Steel Sealed Collets

- ER External Coolant Collets ECD | Jet-Spray

- ER Tap Collets

- ER Tap Sealed Collets

- ER Tap Sealed Jet Spray Collets

- Quick Change Tapping Adapters

- DA Collets Regular

- DA Sealed Collets

- TG Collets

- TG Sealed Collets

- TG Tap Collets

- OZ Collets

- SK Collets | Super Collets

- Straight Collets For Milling Chucks

- Reducation Sleeves For Hydraulic Chucks

- R8 Collets

- Collet Sets

- 5C Collets

- 16C Collets

- 3J Collets

- ER Collet Holders

- Side Lock Endmill Holders

- Shrink Fit Holder

- Facemill Holders

- Morse Taper Holder

- Power Milling Holders

- Hydraulic Holders

- Quick Change Tapping Holders

- ER Straight Shank

- BT Knobs

- CNC Turret Sleeves

- Revolving Live Centers

- ER Collet Nut

- SK Collet Nuts

- ER Spanners

- Tool Locking Device

- Soft Jaws

- Hard Jaws