- No products in the cart.

Revolving live centers are a device that rotates with the workpiece in the machine during machining operations. It is used to support the heavy part ofthe workpiece to rotate faster and provide efficient cutting.

Features :

- Point types extended, profiled, and stud

- Available MT Type - MT3, MT4, MT5

- There are three categories available - Integral Model, Interchangeable Model, Slimline Model.

- Reduce friction wear

- More robust cutting

- High precision and surface quality

Frequently Asked Questions

1. When should I use the live centers in a machine?

It is good to use

live centers that are typically used for high-precision, high-speed operations, because live centers have rotating designs so it minimizes heat that is produced while operating.

2. When is it good to use live centers?

It is good to use

live centers when you need to perform high-speeding operations, slower and to support long workpieces on lathe that rotate with the workpiece and reduce the friction.

3. What are the advantages of using live centers?

The advantages of using

live centers are:

- It provides high-precision performance

- Reduces friction and heat

- Allows higher rotational speed which improves performance

- Rotating design requires less oiling and grease

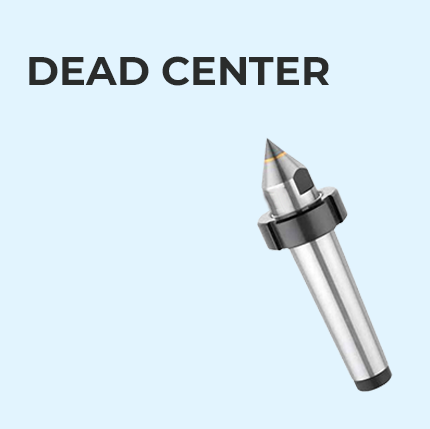

4. What is the difference between live and dead centers?

At Accu-fix precision tools, we offer high-quality

live centers and dead centers for various machining needs.

- Live centers rotate with the workpiece, reducing friction and heat, making them ideal for high-speed machining.

- Dead centers stay fixed, providing stability for low-speed, heavy-duty work.

5. How can I ensure the proper installation of revolving live centers?

Proper installation of

live centers includes:

- Aligning the centers with the workpiece

- Securely supporting them in the machine

- Following your machine’s guidelines

Quick Link

- ER Collet

- ER Sealed Collets

- ER Steel Sealed Collets

- ER External Coolant Collets ECD | Jet-Spray

- ER Tap Collets

- ER Tap Sealed Collets

- ER Tap Sealed Jet Spray Collets

- Quick Change Tapping Adapters

- DA Collets Regular

- DA Sealed Collets

- TG Collets

- TG Sealed Collets

- TG Tap Collets

- OZ Collets

- SK Collets | Super Collets

- Straight Collets For Milling Chucks

- Reducation Sleeves For Hydraulic Chucks

- R8 Collets

- Collet Sets

- 5C Collets

- 16C Collets

- 3J Collets

- ER Collet Holders

- Side Lock Endmill Holders

- Shrink Fit Holder

- Facemill Holders

- Morse Taper Holder

- Power Milling Holders

- Hydraulic Holders

- Quick Change Tapping Holders

- ER Straight Shank

- BT Knobs

- CNC Turret Sleeves

- Revolving Live Centers

- ER Collet Nut

- SK Collet Nuts

- ER Spanners

- Tool Locking Device

- Soft Jaws

- Hard Jaws